Tarp welding machines - a key element in tarpaulin top production

What are the heat welding machines used for the production of tarpaulins?

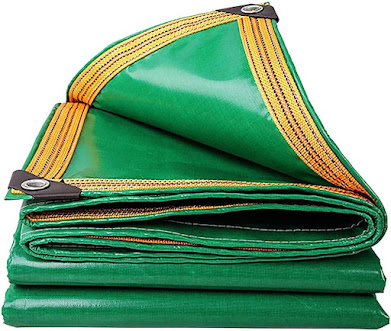

Tarpaulin covers are versatile and valuable items used in various industries. To deliver or assemble them into larger designs, utilizing appropriate tools is necessary. Heat sealing and welding machines are a great way to join materials rapidly and productively. In this article, we'll talk about what you can join with a heat welding machine, how to interface two tarpaulin sheets, what welding machines do, and which one is really great for making tarpaulin and sun cover items.

The most well-known kinds of tarp welding machines are:

Motivation welders/sealing machines: They pass power through a particular resistive material while squeezed, heating it up. Drive welders create pressure, dissolve materials, and make serious areas of strength for a weld.

Hot Air Welders: Using the generation of hot air to disintegrate the material and allow it to weld. Welding is finished by pressing the appropriate fragments of the material while feeding hot air.

High-recurrence welding machines: Using high-recurrence heating innovation, these welders create weld areas of strength for the original material. The cycle depends on material properties to generate heat in a variable electromagnetic field. These welders work for certain materials. High-recurrence welding involves subjecting associated parts to a high-recurrence electromagnetic field (often 27.12 MHz), regularly used between two metal conductors.

Tarp welding machines have wide purposes across various industries:

Development and renovations: Tarpaulins safeguard materials on building destinations from the weather. Welding machines join tarpaulins to protect against rain, wind, and sun.

Transportation: Trucks and trailers use tarpaulins to get cargo. Welding guarantees they get through harsh roads and conditions.

Agriculture: Tarpaulins shield crops from weather and act as covers in agricultural passages. Welding easily interfaces tarpaulins where required.

Gardening: Tarpaulins safeguard plants from ice, bugs, and inordinate daylight. Welding definitively associates tarpaulins, which are crucial for complex shapes.

How do you bond tarpaulin materials?

Making tarpaulins and covers is evolving with innovation for proficiency and durability. Beforehand, tarpaulins were sewn, however, today, it is necessary to weld machines. PVC is a typical tarpaulin material, resistant to tearing and weather. UV openness can fade it, however, present-day PVC film advancements add UV channels. Welding is the way to join PVC successfully.

Connecting two tarpaulin fabrics

To join two tarpaulins, utilize hot air, drive welding, or high-recurrence welding machines. Drive welding machines like PULSA ECO and PULSA SUPRIM by Zemat Innovation Gathering are financially savvy and practical. Their long worktables allow exact, fast joining. For larger designs, consider high-recurrence welding with a moving head like TARPA Expert, for long, cyclic linear welds.

It relies upon the maker's requirements, PVC Tarpaulin, and type. For smaller parts like truck covers, the SIMPLE machine with a 1200 mm terminal is suitable. For greater, advanced structures, drive welders like PULSA ECO and PULSA ECO are suggested.

Also, TARPA Star, an automated moving welder, suits large designs with technical fabrics like PVC, PU, TPU, and PE. It handles wide cyclic welds up to 1500 mm, enabling intricate tarp plans.

HF and Motivation welding advantages for tarpaulin

Solid bonds: Welding creates durable tarpaulin associations, extending material lifespan.

Time and labor savings: Manual tarpaulin associations are slow; welding automates the interaction, saving time and effort.

Accuracy and esthetics: Welding guarantees accurate, even joins for an attractive final item.

Safety: Welding is safe, no vapor or PVC smoke is generated during hot air welding.

Zemat welding machines for tarp production

Quality tarpaulins require specialized tools for durability and esthetics. Zemat Innovation Gathering machines are brilliant for achieving top-level outcomes in tarp production. Using advanced innovation and specialized machinery, tarpaulin makers can create excellent items tailored to their necessities. Investigate Zemat Innovation Gathering's offerings to find the right welding machine for your tarpaulin production, ensuring outcome in a cutthroat market.

Comments

Post a Comment